Full-Automatic Heat Pump Dry System

Lage scale drying line design ,high temperature drying, efficient dehumidification and conveyor belt material transport mode, not only can batch uninterrupted material transport to the drying line, achieve mass production, multi-layer conveyor belt and back transport mode, but also can play the role of turning over materials in the transportation process, greatly increasing the contact area and contact time between materials and hot air. The drying speed is fast, and drying and dehumidification effect are good. The whole system is enclosed in circulation, free of dust and particulate matter pollution to the atmosphere. covering a small area, suitable for large and medium-sized industrial dryer treatment.

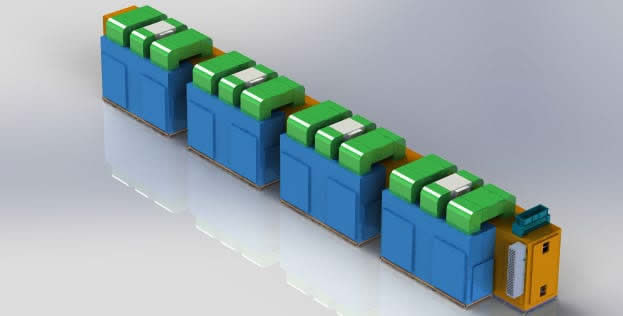

The standard drying line is 6 meters. Now we take a example of 24 meters modular system design, high temperature drying, efficient dehumidification and conveyor belt material transport mode, not only can batch uninterrupted material transport to the drying line, achieve mass production, multi-layer conveyor belt and back transport mode, but also can play the role of turning over materials in the transportation process, greatly increasing the contact area and contact time between materials and hot air. The drying speed is fast, and drying and dehumidification effect are good. The Full-Automatic Heat Pump Drysystem is enclosed in circulation, free of dust and particulate matter pollution to the atmosphere. The system is equipped with high-voltage electric field sterilization.

Features

1.Closed cycle drying, no pollution to the atmosphere and surrounding environment, in line with the requirements of environmental protection.

2.Conveyor belt material transportation can realize bulk material drying.

3.Quick drying, good effect and significant energy saving.

4.High pressure electric field sterilization.

5.Fully automatic operation, no need for manual supervision.

6.Batch continuous and automatic drying.

7.Quickly drying to reduce material moisture content.

8.Modular unit, small occupation area, easy to adjust equipment operation position.

9.No infrastructure required.

Product details

TECHNICAL SPECIFICATIONS

| Model | DY-6M/48P |

DY-12M/96P |

DY-24M/192P |

| Size (length*width*height)(mm) | 6*2.24*2.6 m |

12*2.24*2.6 m |

24*2.24*2.6 m |

| Equipment drying structure | 4 layers of plastic chain plate +1 layer of recovery |

||

| Equipment drying system | Heat pump dehumidification |

||

|

304 stainless steel |

||

| feed moisture content | 85% |

||

| Water content of discharge | 20-30% |

||

| Energy consumption of dehydration(KG/KWH) | 3 |

||

| Dehydration per hour(kg/h) | 120 |

250 |

500 |

| Daily dehydration(kg) | 2400 |

5000 |

10000 |

| Daily goods treatment(kg) | 3000-5000 |

6000-8000 |

13000-15000 |

| Voltage(V)/Frequency(HZ) | 400V /50HZ |

||

| Total power(KW) | 40 |

80 |

150 |

| Rated current(A) | 80 |

150 |

286 |

| Heat pump configuration power(HP) | 48 |

96 |

192 |

| Heat pump air inlet temperature(℃) | 80-85 |

||

| Heat pump air inlet humidity(%) | 10%-15% |

||

| Heat pump return air temperature(℃) | 45-55 |

||

| Heat pump return air humidity(%) | 50%-70% |

||

| Controller | Touch screen +PLC programmable controller |

||

|

Class 1 |

||

| Protection class | 1P×4 |

||

| Environment temperature(℃) | 0-40 |

||

| Noise[dB(A)] | 55 |

||

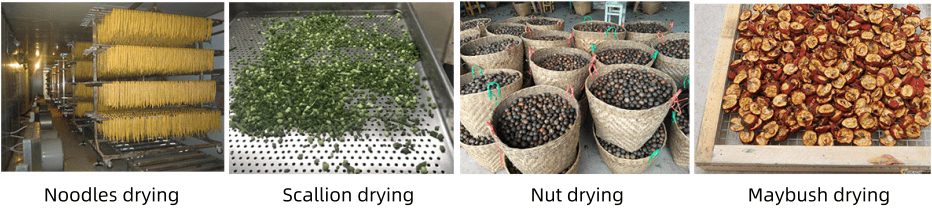

Application

The Full-Automatic Heat Pump Drying production line widely used in vegetable drying,fruit drying,nut drying,food drying,etc.

Project photos

Scallion drying

Nut drying

Noodles drying

Processing capability